One of Hottest for Fep Film Manufacturers - FEP Resin (DS610H&618H) – Huaxia Shenzhou

One of Hottest for Fep Film Manufacturers - FEP Resin (DS610H&618H) – Huaxia Shenzhou Detail:

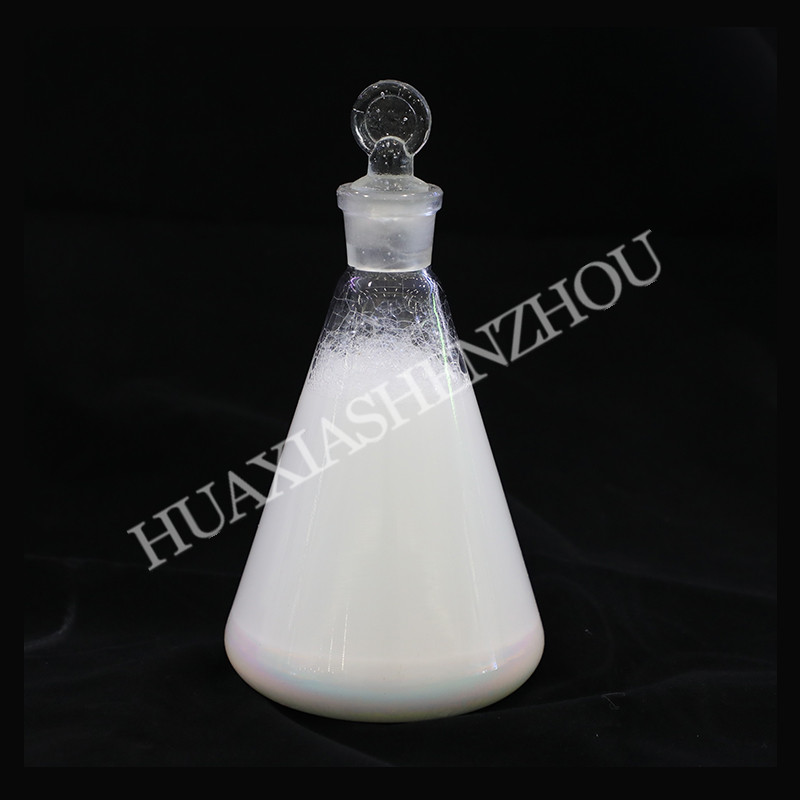

FEP DS618 series is a melt-processible copolymer of tetrafluoroethylene and hexafluoropropylene without additives that meets the requirements of ASTM D 2116. FEP DS618 series has good thermal stability, outstanding chemical inertness, good electrical insulation, non-aging characteristics, exceptional dielectric properties, low flammability, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption, and excellent weather resistance.DS618 series has high molecular weight resins of low melt index, with low extrusion temperature, high extrusion speed which is 5-8 times of ordinary FEP resin.It is soft, anti-burst, and has good toughness.

Conformable with Q/0321DYS 003

Technical Indexs

| Item | Unit | 610H | DS618H | Test Method/Standards |

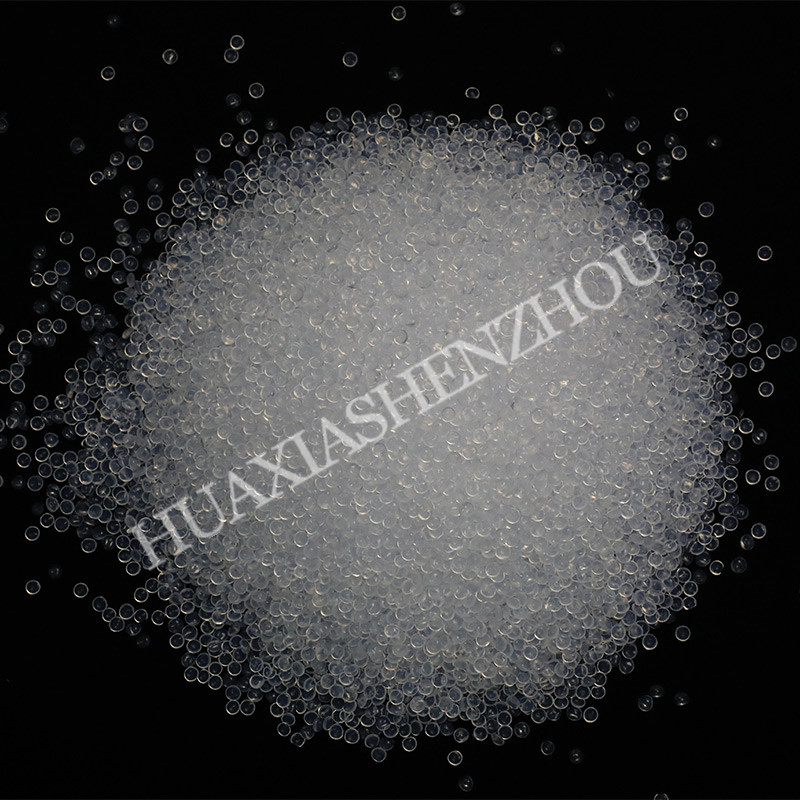

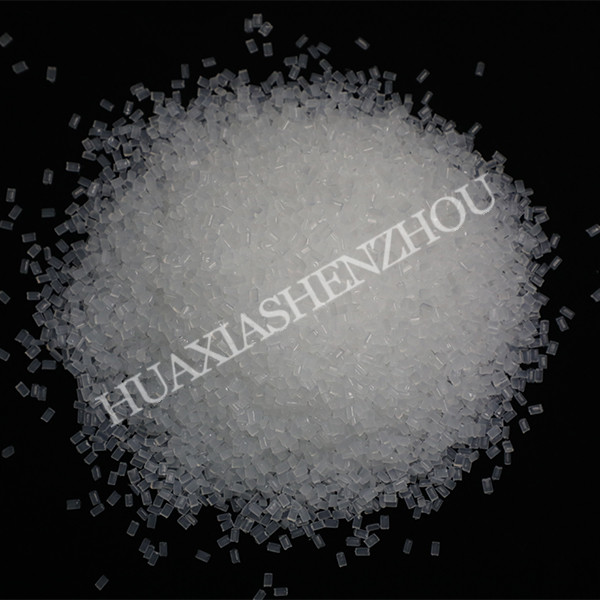

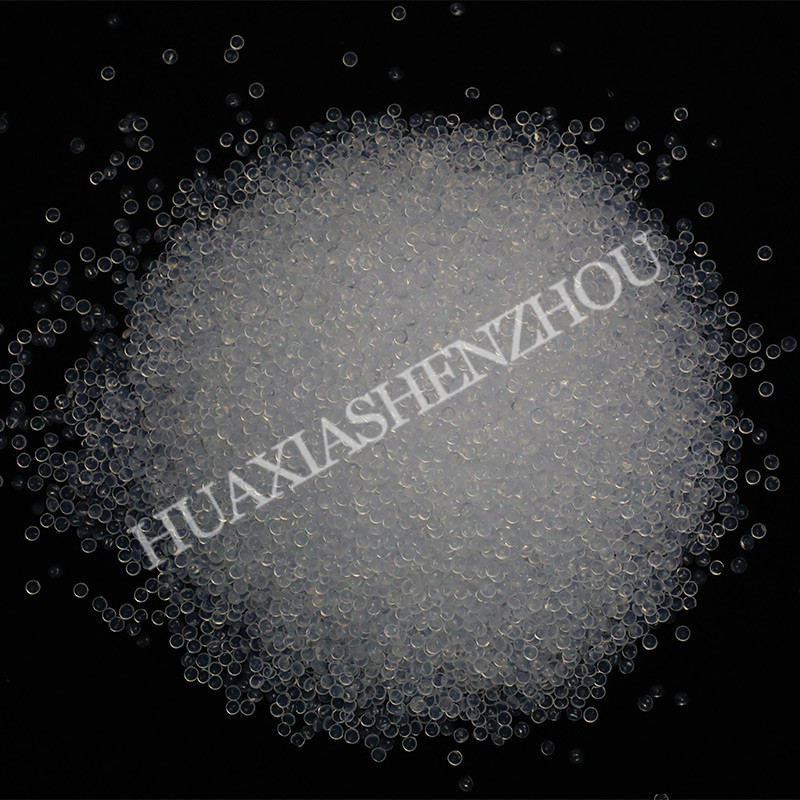

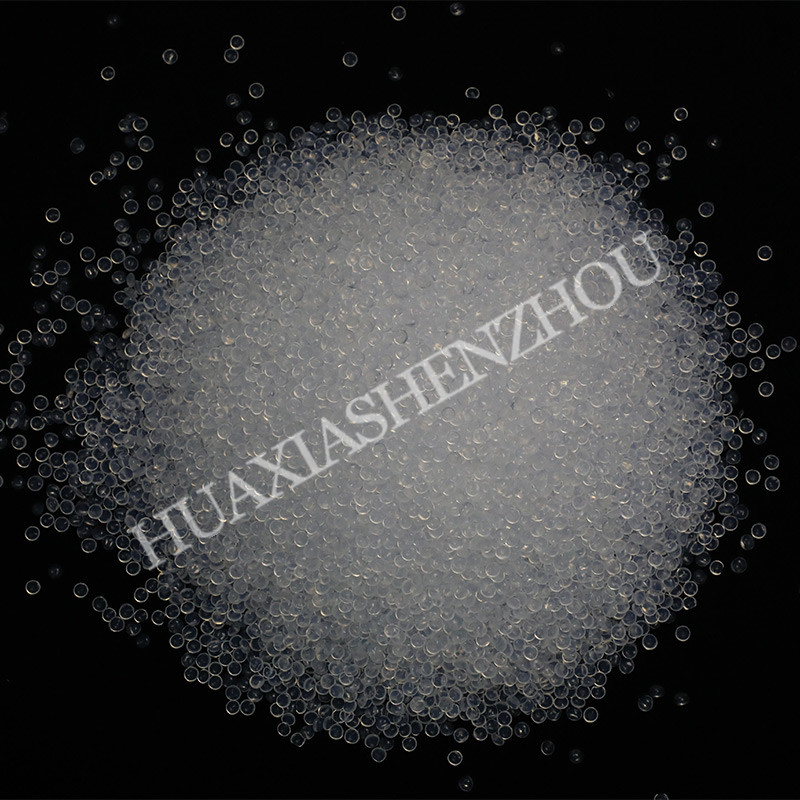

| Appearance | / | Translucent particle,with impurities such as metal debris and sand,containing visible black particles percentage point less than 1% | HG/T 2904 | |

| Melting Index | g/10min | 5.1-12.0 | 24-42 | GB/T 3682 |

| Tensile Strength,≥ | MPa | 25 | 21 | GB/T 1040 |

| Elongation at break,≥ | % | 330 | 320 | GB/T 1040 |

| Relative Gravity | / | 2.12-2.17 | GB/T 1033 | |

| Melting Point | ℃ | 265±10 | GB/T 28724 | |

| Dielectric Constant(106HZ),≤ | / | 2.07 | GB/T 1409 | |

| Dielectric Factor(106HZ),≤ | / | 5.7×10-4 | GB/T 1409 | |

| MIT≥ | cycles | 30000 | / | ASTM/D2176 |

| Item | Unit | 610H | DS618H | Test Method/Standards |

Application

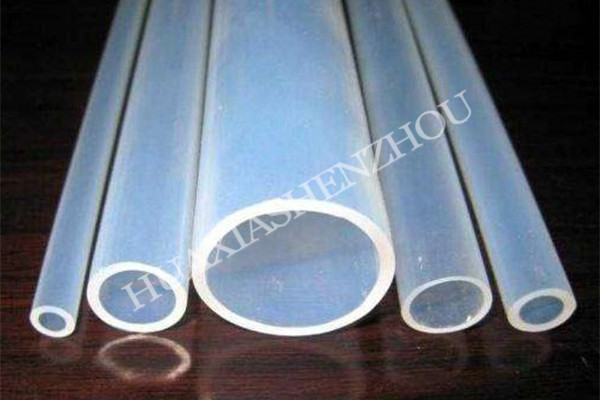

Mainly in the MTR transport vehicles, automatic switching equipment, well test equipment, flame alarm systems, high-rise building, fire regional wires, cables, computers, communication networks, electrical fields, particularly applicable for high-speed extrusion small-caliber wire insulation material.It is more economical when used in where no high stress cracking resistance is required.

Attention

The processing temperature should not exceed 420℃, to prevent toxic gas from releasing.

Package, Transportation and Storage

1.Packed in plastic bag of 25kgs net each.

2.Stored in clean, cool and dry places,to avoid contamination from foreign substances such as dust and moisture.

3.Nontoxic, noninflammable, inexplosive, no corrosion, the product is transported according to non-dangerous product.

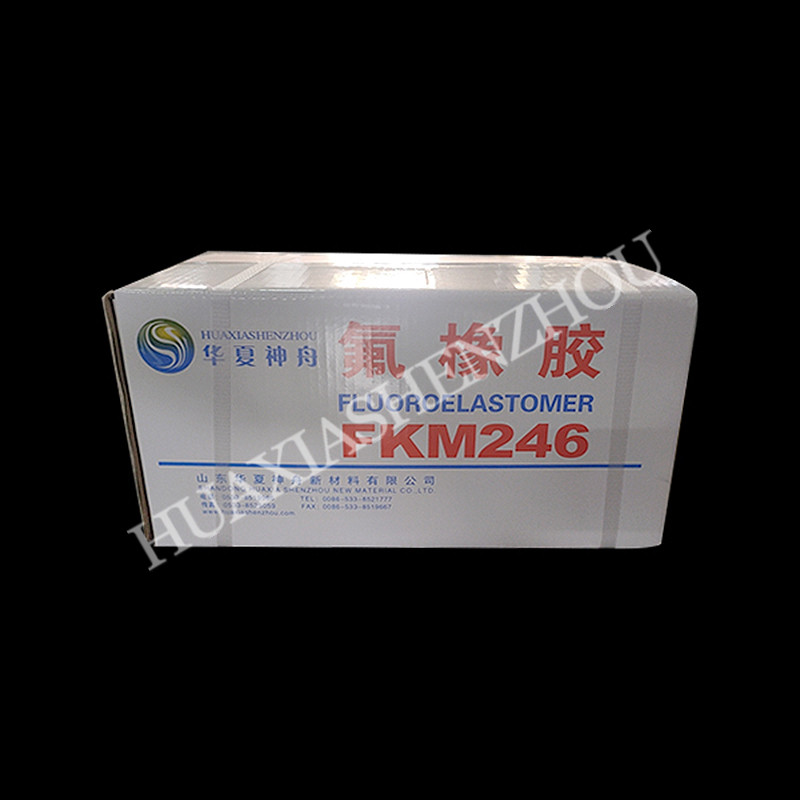

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for One of Hottest for Fep Film Manufacturers - FEP Resin (DS610H&618H) – Huaxia Shenzhou , The product will supply to all over the world, such as: Nairobi, Iran, New York, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.