China Manufacturer for Fep Film - FEP Resin (DS618) for jacket of high speed and thin wire & cable – Huaxia Shenzhou

China Manufacturer for Fep Film - FEP Resin (DS618) for jacket of high speed and thin wire & cable – Huaxia Shenzhou Detail:

FEP DS618 series is a melt-processible copolymer of tetrafluoroethylene and hexafluoropropylene without additives that meets the requirements of ASTM D 2116. FEP DS618 series has good thermal stability, outstanding chemical inertness, good electrical insulation, non-aging characteristics, exceptional dielectric properties, low flammability, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption and excellent weather resistance. DS618 series has high molecular weight resins of low melt index, with low extrusion temperature, high extrusion speed which is 5-8 times of ordinary FEP resin.

Conformable with Q/0321DYS 003

Technical Indexs

| Item | Unit | DS618 | Test Method/Standards | Item | |||

| A | B | C | D | ||||

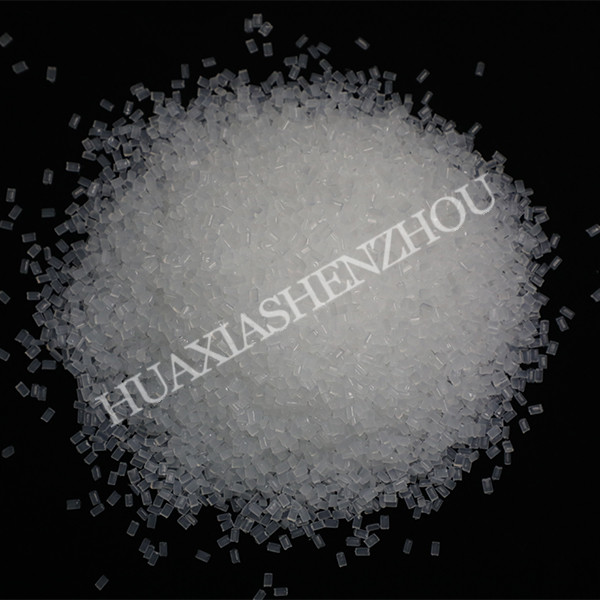

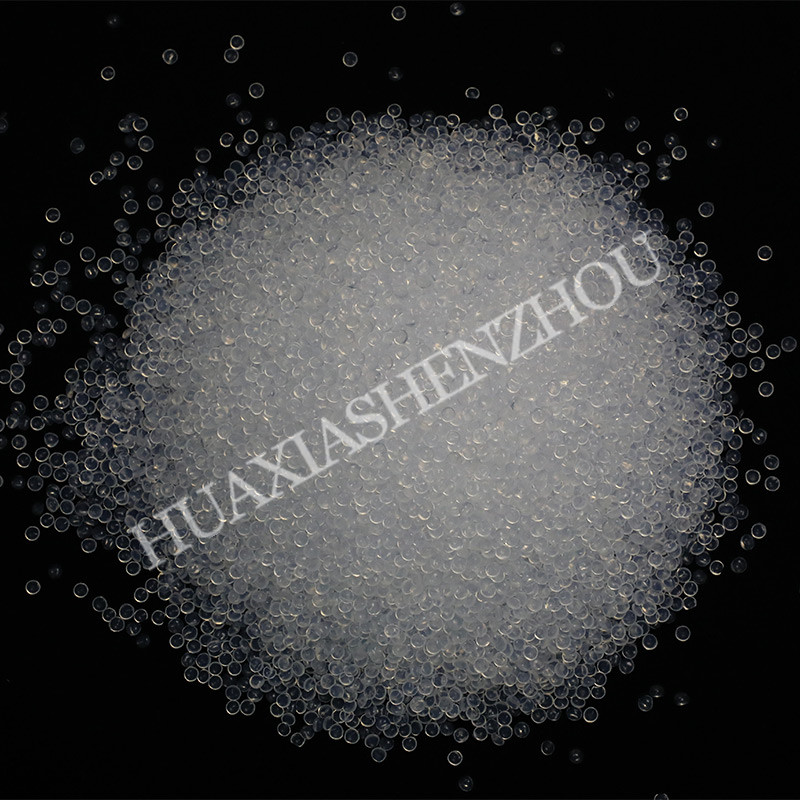

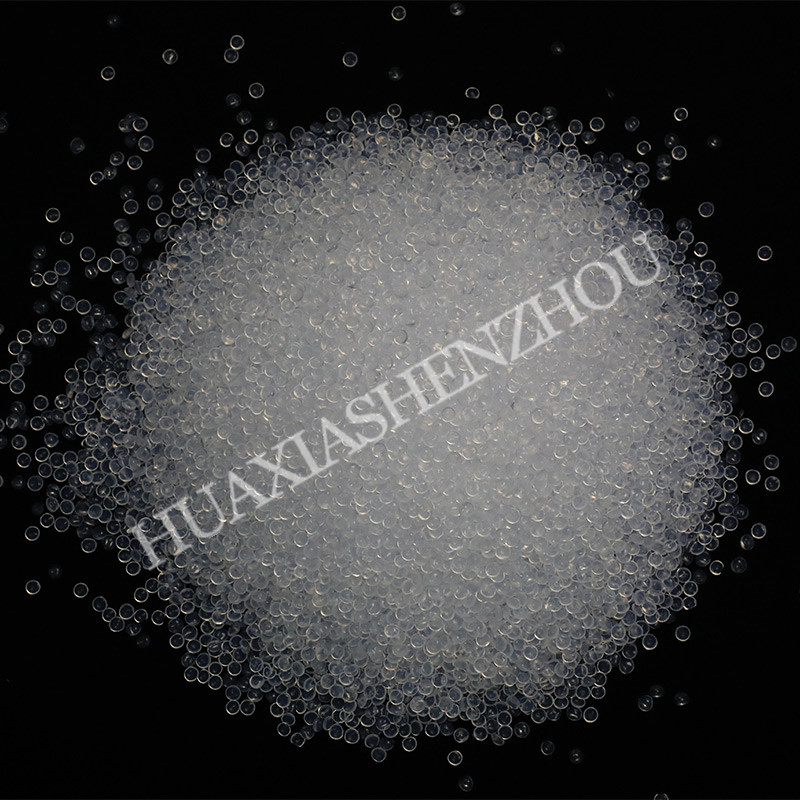

| Appearance | / | Translucent particle,with impurities such as metal debris and sand,containing visible black particles percentage point less than 1% | HG/T 2904 | Appearance | |||

| Melting Index | g/10min | 16.1-20.0 | 20.1-24.0 | ≥24.1 | 12.1-16.0 | ASTM D2116 | Melting Index |

| Tensile Strength,≥ | MPa | 20 | 18 | 17.5 | 20 | ASTM D638 | Tensile Strength,≥ |

| Elongation at break,≥ | % | 300 | 280 | 280 | 300 | ASTM D638 | Elongation at break,≥ |

| Relative Gravity | / | 2.12-2.17 | ASTM 792 | Relative Gravity | |||

| Melting Point | ℃ | 265±10 | ASTM D4591 | Melting Point | |||

| Dielectric Constant(106HZ),≤ | / | 2.15 | ASTM D1531 | Dielectric Constant(106HZ),≤ | |||

| Dielectric Factor(106HZ),≤ | / | 7.0×10-4 | ASTM D1531 | Dielectric Factor(106HZ),≤ | |||

| Item | Unit | DS618 | Test Method/Standards | Item | |||

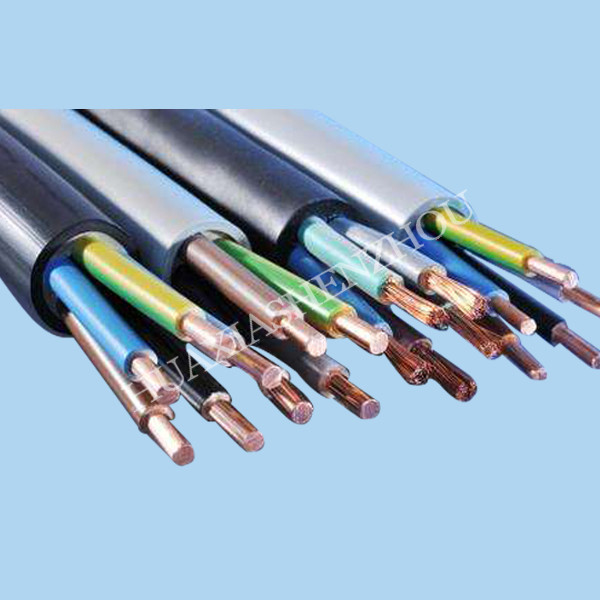

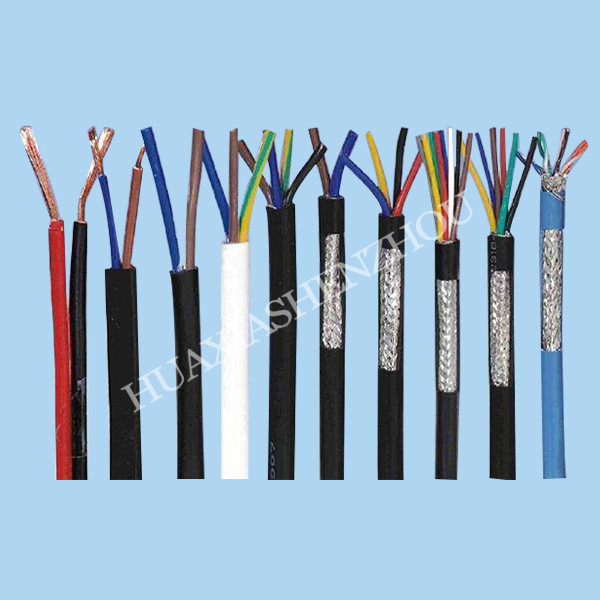

Application

Mainly in the MTR transport vehicles, automatic switching equipment, well test equipment, flame alarm systems, high-rise building, fire regional wires, cables, computers, communication networks, electrical fields, particularly applicable for high-speed extrusion small-caliber wire insulation material.It is more economical when used in where no high stress cracking resistance is required.

Attention

The processing temperature should not exceed 420℃, to prevent toxic gas from releasing.

Package, Transportation and Storage

1.Packed in plastic bag of 25kgs net each.

2.Stored in clean, cool and dry places,to avoid contamination from foreign substances such as dust and moisture.

3.Nontoxic, noninflammable, inexplosive, no corrosion, the product is transported according to non-dangerous product.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of China Manufacturer for Fep Film - FEP Resin (DS618) for jacket of high speed and thin wire & cable – Huaxia Shenzhou , The product will supply to all over the world, such as: Jamaica, Russia, Ecuador, We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products supremely adored and appreciated by our customers worldwide.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.