8 Year Exporter Fkm Viton Seal - Low Temperature Resistant FKM – Huaxia Shenzhou

8 Year Exporter Fkm Viton Seal - Low Temperature Resistant FKM – Huaxia Shenzhou Detail:

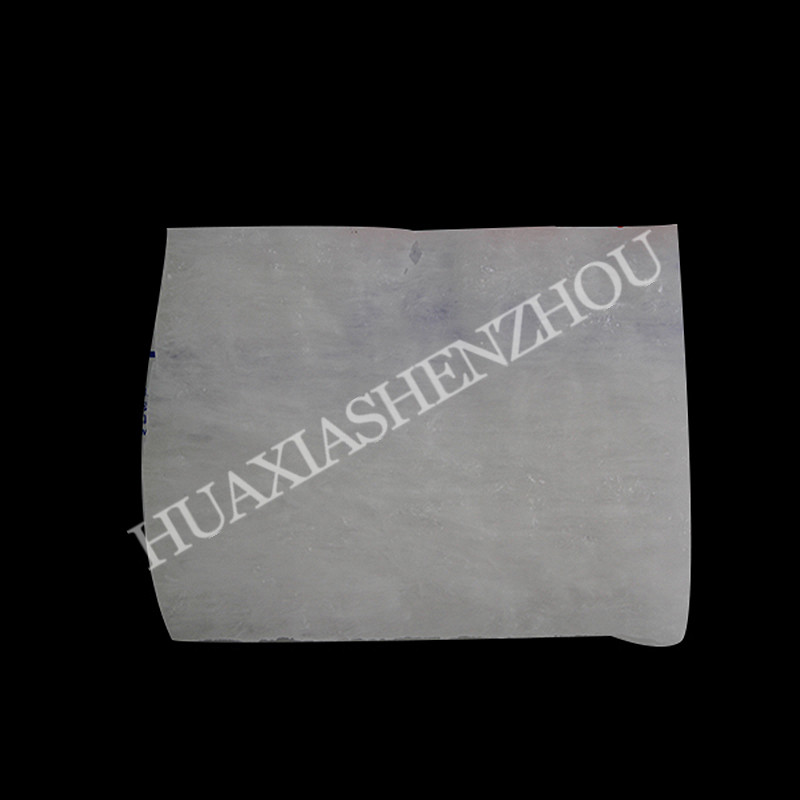

Fluoroelastomer FKM Terpolymer Gum-246 series are the terpolymer of vinylidenefluoride, tetrafluoroethylene and hexafluoropropylene.Because of its high fluorine content, its vulcanized rubber has excellent anti oil property and high thermal stability.It also has good mechanical property and can be used in 275℃ for a long time, in 320℃ for a short time.The property of antil oil and anti acid is better than FKM-26, resistance of FKM246 to oil, ozone, radiation, electricity and flamer is similar with FKM26.

Execution standard:Q/0321DYS 005

Quality Specification

| Item | 246D | Test Method/Standards |

| Density,g/cm³ | 1.82±0.02 | GB/T533 |

| Mooney Viscosity,ML(1+10)121℃ | 55-62 | GB/T1232-1 |

| Tensile Strength,MPa≥ | 12 | GB/T528 |

| Elongation at break,%≥ | 180 | GB/T528 |

| Compression Set(200℃,70h),%≤ | 25 | GB/T7759 |

| Fluorine Content,% | 66 | / |

| Characteritics and Application | Best low temperature flexibility and sealing,-20℃ | / |

Note:The above vulcanization systems are bisphenol AF

Product Use

FKM246 is widely used in aerospace, automotive, machinery, petrochemical, and other fields.For example, the aircraft static/ dynamic seals materials of hydraulic system and lubrication system;used in drilling equipment and oil pipelines;the chemical industry for equipment, flexible pipe connections, liner of pump or corrosion-resistant sealing material, made of pipes to carry solvents or other media, such as corrosion.

Attention

1.Fluoroelastomer terpolymer rubber has good heat stability under 200℃.It will generate trace decomposition if being put at 200-300′C for a long time, and its decomposing speed accelerates at above 320℃, the decomposition products are mainly toxic hydrogen fluoride and fluorocarbon organic compound.When raw fluorous rubber encounters fire, it will release toxic hydrogen fluoride and fluorocarbon organic compound.

2.FKM cannot be mixed with metal powder such as aluminum powder and magnesium powder, or over10% amine compound, if that happens, temperature will arise and several element will react with FKM, which will damage the equipment and operators.

Package, Transportation and Storage

1.FKM is packed in PE plastic bags, and then loaded into cartons, the net weight of each carton is 20kg.

2.FKM is stored in clean, dry and cool warehouse.It is transported according to non-hazardous chemicals, and should keep away from pollution source, sunshine and water during transportation.

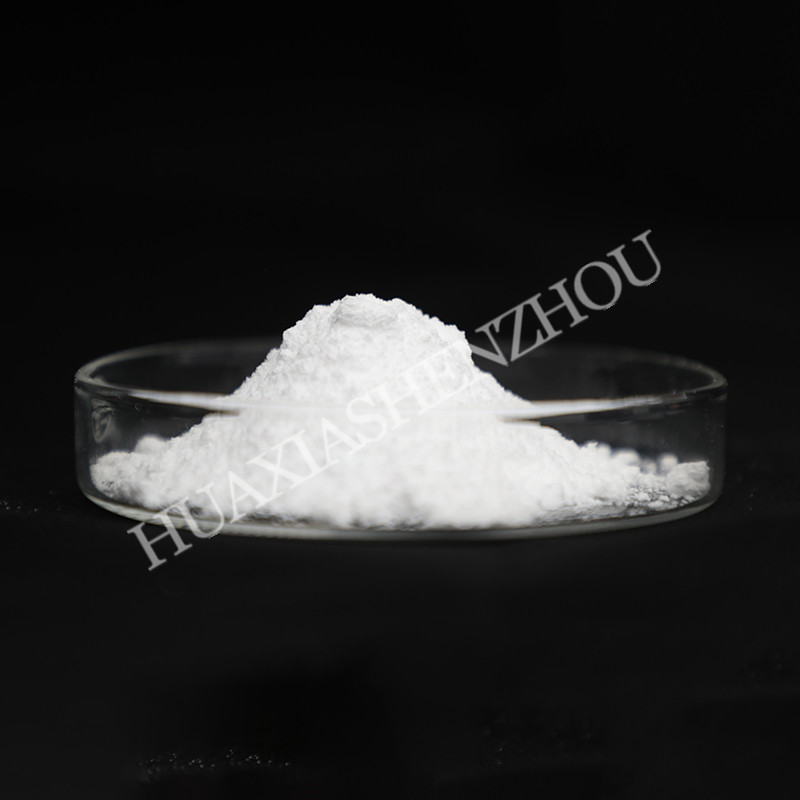

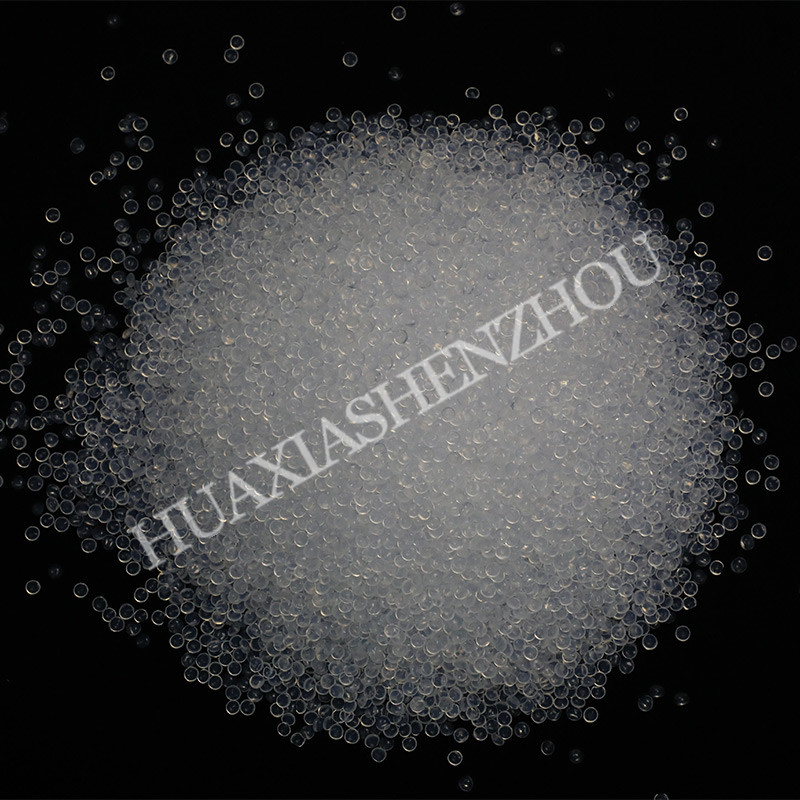

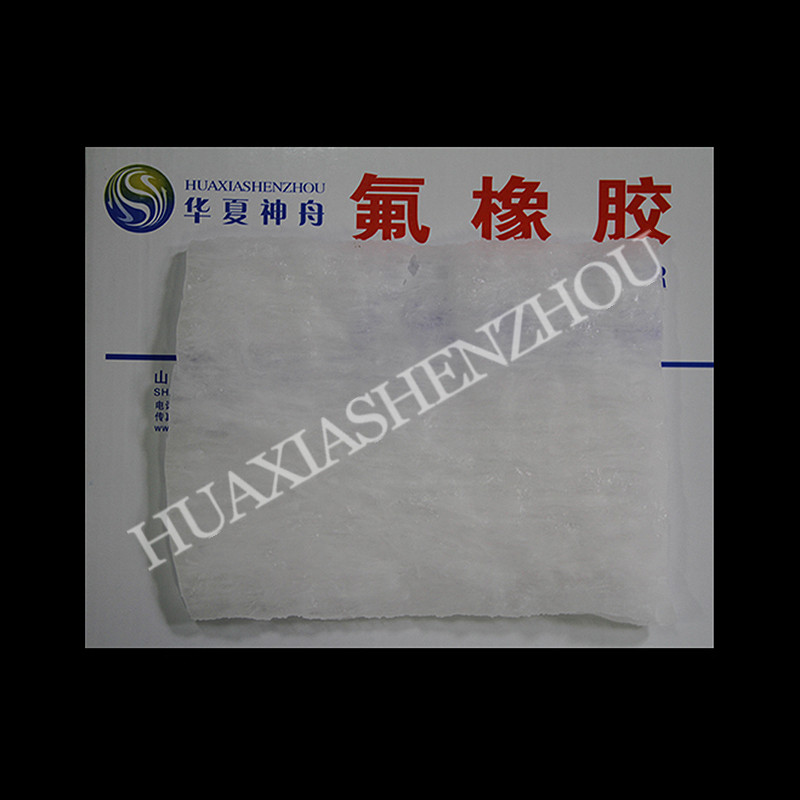

Product detail pictures:

Related Product Guide:

Our intention is usually to satisfy our buyers by offering golden provider, great rate and good quality for 8 Year Exporter Fkm Viton Seal - Low Temperature Resistant FKM – Huaxia Shenzhou , The product will supply to all over the world, such as: Sheffield, Puerto Rico, Egypt, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.