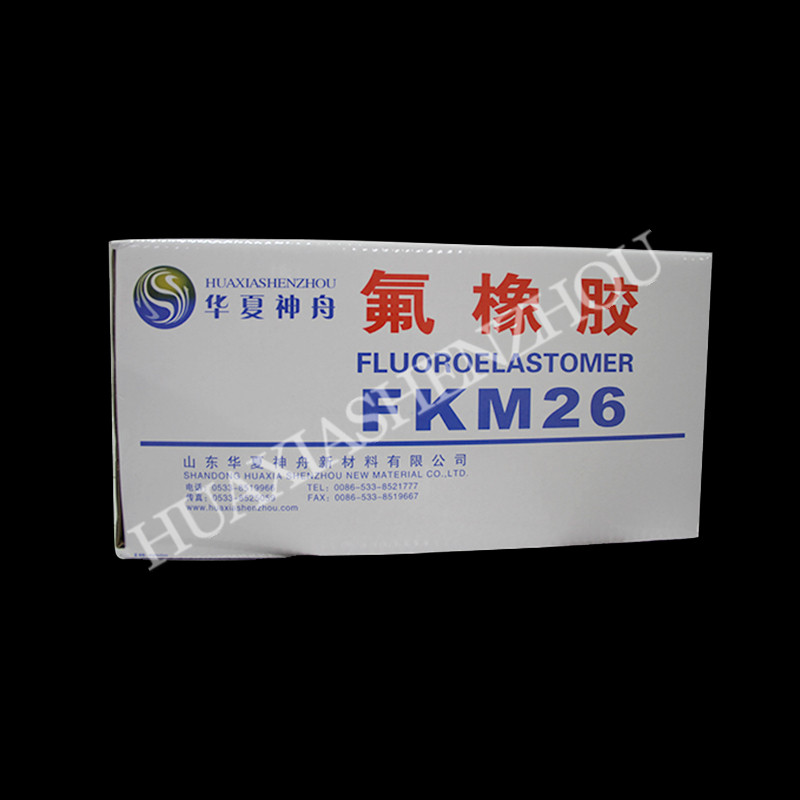

2022 New Style Material Fkm Viton - FKM (Copolymer)fluoroelastomer Gum-26 – Huaxia Shenzhou

2022 New Style Material Fkm Viton - FKM (Copolymer)fluoroelastomer Gum-26 – Huaxia Shenzhou Detail:

FKM copolymer Gum-26 series are the copolymer of vinylidenefluoride and hexafluoropropylene, whose fluorine content is over 66%.After valcanizing process, the products have excellent mechanical performance, outstanding anti oil property(fuels, synthetic oils, lubricating oils)and heat resistance, which can be used in the fields of modem aviation, rocket, missile, space flight, etc.

Execution standard:Q/0321DYS005

Technical Indexs

| Item | 26M | Test Method/Standards |

| Density,g/cm³ | 1.82±0.02 | GB/T 533 |

| Mooney Viscosity,ML(1+10)121℃ | 20-25 30-35 55-60 60-66 |

GB/T 1232-1 |

| Tensile Strength,MPa≥ | 12 | GB/T 528 |

| Elongation at break,%≥ | 180 | GB/T 528 |

| Compression Set(200℃,70h),%≤ | 15 | GB/T 7759 |

| Fluorine Content,% | 66 | / |

| Characteritics and Application | Excellent procession for extrusion and injection molding |

/ |

Note: The above vulcanization systems are bisphenol AF

Product Use

Widely used for manufacturing washers, gaskets, O-rings, V-rings, oil seals, diaphragms, rubber pipes, cable sheaths, heat insulation cloth, valve plates, expansion joints, rubber rolls, coatings and pasty room temperature vulcanization putties in occasions resisting high temperature, fuel(aviation gasoline, auto fuel),lubricating oil(synthetic oils),fluid(various non-polar solvents).corrosion(acid, alkali),strong oxidizer(oleum),ozone, radiation and weathering.

Attention

1. FKM has good heat stability under 200℃.It will generate trace decomposition if being put at 200-300℃ for a long time, and its decomposing speed accelerates at above 320℃,the decomposition products are mainly toxic hydrogen fluoride and fluorocarbon organic compound.When raw fluorous rubber encounters fire, it will release toxic hydrogen fluoride and fluorocarbon orgainc compound.

2. FKM cannot be mixed with metal powder such as aluminum powder and magnesium powder, or over 10% amine compound, if that happens, temperature will arise and several element will react with FKM, which will damage the equipment and operators.

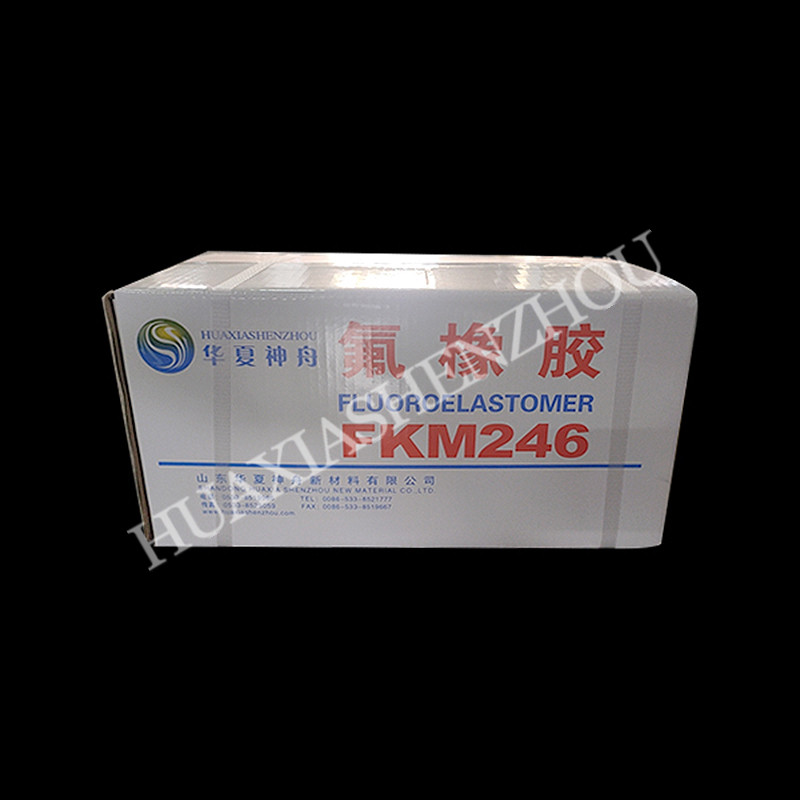

Package, Transportation and Storage

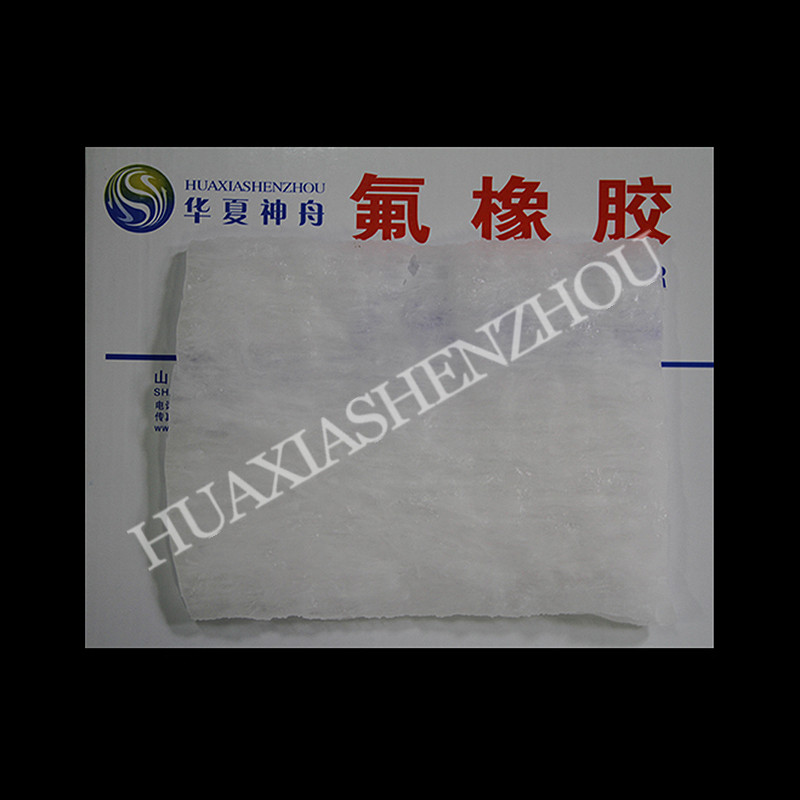

1.FKM is packed in PE plastic bags, and then loaded into cartons, the net weight of each carton is 20kg.

2.FKM is stored in clean, dry and cool warehouse.It is transported according to non-hazardous chemicals, and should keep away from pollution source, sunshine and water during transportation.

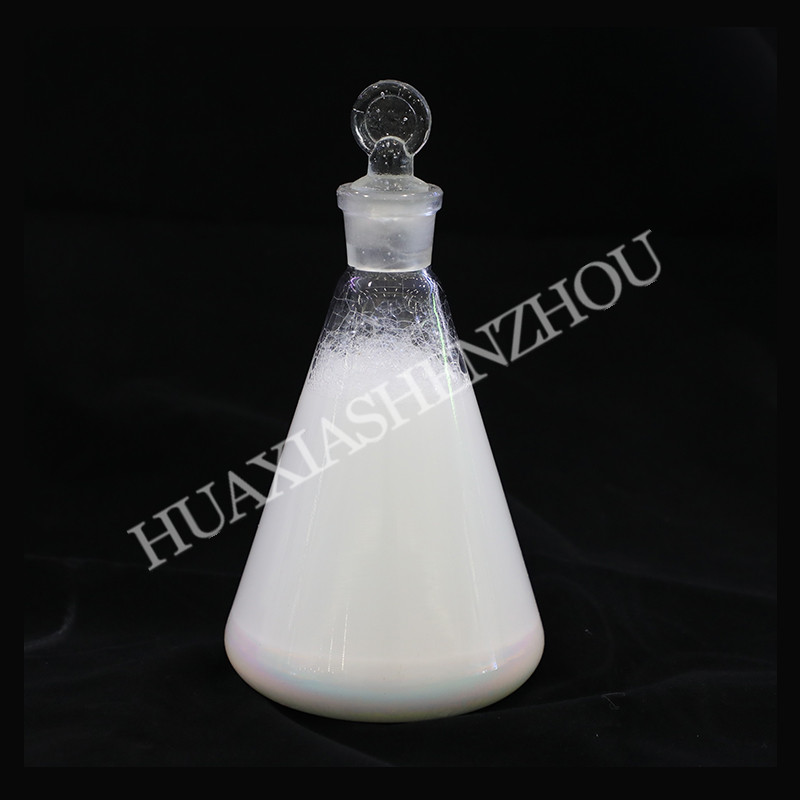

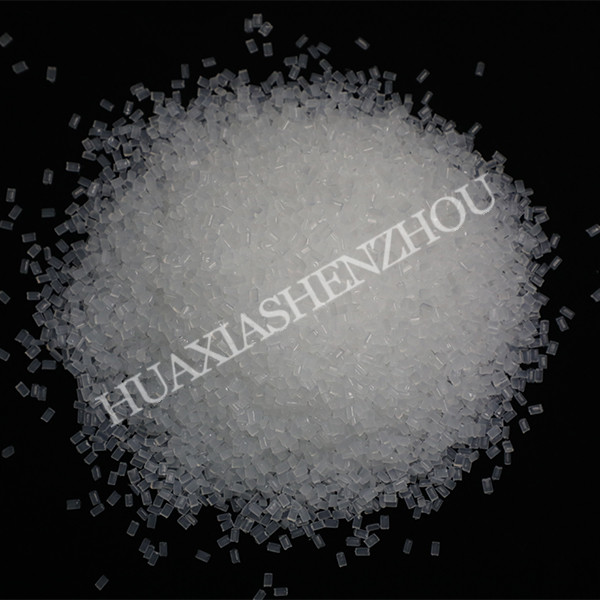

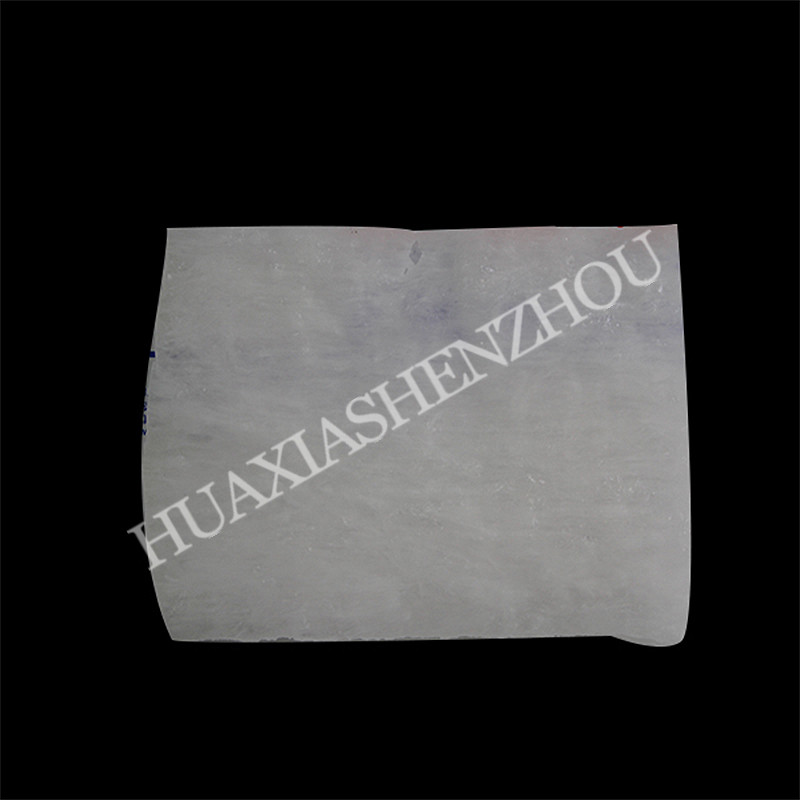

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for 2022 New Style Material Fkm Viton - FKM (Copolymer)fluoroelastomer Gum-26 – Huaxia Shenzhou , The product will supply to all over the world, such as: Dominica, Rotterdam, Bandung, With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.